- Home

- >

- News

- >

- Industry News

- >

News

On November 22, 2024, SYTOP finished a new batch of transition pieces seals designed for GE turbines. These high-performance seals, made from cobalt-based alloys, provide reliable, long-lasting protection against leaks in critical turbine systems. The new seals are engineered to withstand high pressures and temperatures, ensuring GE turbines' optimal performance and longevity.

On November 21, 2024, SYTOP explored the critical differences between tungsten carbide and cobalt alloy in industrial applications. The comparison focuses on their material properties, wear resistance, temperature tolerance, and cost-effectiveness. This analysis is designed to help industries select the best material for their specific requirements, ensuring reliability and efficiency in challenging environments.

High-pressure homogenizer valves are critical components in various industrial processes, especially in food processing, chemical, and pharmaceutical industries, where stability and durability are essential. As a specialized manufacturer of cobalt alloys, we focus on producing high-quality, high-pressure homogenizer valve components that leverage the exceptional properties of cobalt alloys. Our products meet the industry’s demand for high-performance, highly reliable, and long-lasting parts. This article will explore the importance of high-pressure homogenizer valves, the advantages of cobalt alloy for these components, our production capabilities, and our custom services.Cobalt Alloy High-Pressure Homogenizer Valve Components

On October 23, 2024, SYTOP published a comparison of Wallex® and Colmonoy® hardfacing materials. This analysis highlights the main differences between these two alloys, focusing on their composition, applications, and performance characteristics.

When selecting materials for high-performance applications, cobalt alloys and 316L stainless steel are two options that are often considered. Both materials offer unique advantages but excel in different environments and applications. In this article, we compare the properties of cobalt alloys and 316L to help you understand which material is best for your needs.

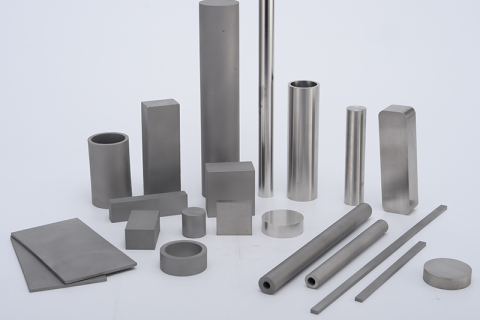

Cobalt alloys are widely used in industries requiring wear and corrosion resistance materials. Cobalt alloys are an excellent solution for demanding applications especially in high temperatures, known for their exceptional durability, wear resistance, and ability to withstand extreme temperatures.

Cobalt alloys are renowned for their exceptional wear resistance, high-temperature endurance, and corrosion protection, making them essential in various industries. But the question remains: Is cobalt alloy hard to machine? This article explores the challenges of machining cobalt alloys and how SYTOP overcomes them to deliver precise, high-quality products.

This News highlighted the advantages of cobalt alloy overlay welding in extending the lifespan of components under extreme working conditions. The technique ensures wear, corrosion, and high-temperature resistance, making it ideal for various industries.

In September 2024, SYTOP prepared to ship another batch of our long-standing cobalt alloy propellers, designed for use in hot-dip galvanizing production lines. These propellers, known for their exceptional wear resistance, high-temperature endurance, and corrosion protection, continue to support the demanding needs of galvanizing processes worldwide.

Cobalt Alloy Grade UNS R30006 is a high-performance material renowned for its exceptional wear and corrosion resistance at elevated temperatures. Part of the Unified Numbering System (UNS), this cobalt-based alloy offers significant advantages in demanding environments, making it a superior choice for applications that require robust material performance. Similarly, UNS R30016 is another notable grade within the cobalt alloy family, offering enhanced characteristics for specific industrial needs.

Cobalt-based superalloys show superior properties than other materials in strength, elasticity, and many other aspects. Let us explore cobalt-based superalloys and understand what they are, their classifications, and where they can be applied.