News

SYTOP, a leading manufacturer of precision-engineered Cobalt alloy custom components, is excited to announce its participation in the 25th China International Petroleum & Petrochemical Technology and Equipment Exhibition (CIPPE) from Mar 26-28, 2025.

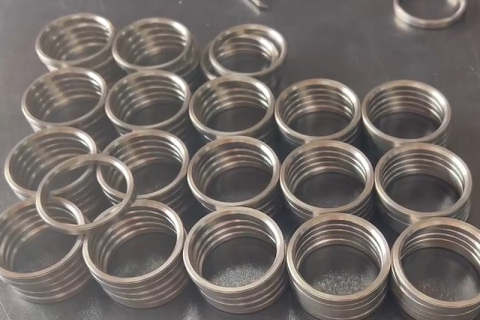

On March 6, 2025, SYTOP has successfully completed the first order of 300 cobalt engine exhaust valve seats from KAMA. The cooperation started on December 12, 2024, when KAMA sent an RFQ to SYTOP for a quantity of 2,000 pieces of valve seats, which were highly valued due to the difficulty of machining, and the first batch of the products has now entered the delivery verification stage.

Steam turbine blades operate in extreme environments with high temperatures, corrosive media, and mechanical stresses. Over time, corrosion and wear degrade blade performance, leading to efficiency losses and costly maintenance. To address these challenges, Alloy 6B/UNS R30016 is a superior material for wear strips and protective overlays on steam turbine blades. This cobalt-chromium-tungsten alloy complies with AMS 5894, combining unmatched corrosion resistance, high-temperature stability, and mechanical durability. This article explores the root causes of turbine blade corrosion and the criteria for material selection.

2025/2/19, a Turkish customer sent an email, hoping that we could introduce the difference between our material and tungsten carbide. He said: "we use them in milk homogenization. original from german as tungstean carbide. can you recomend us your products much better tan tc mtrl?"

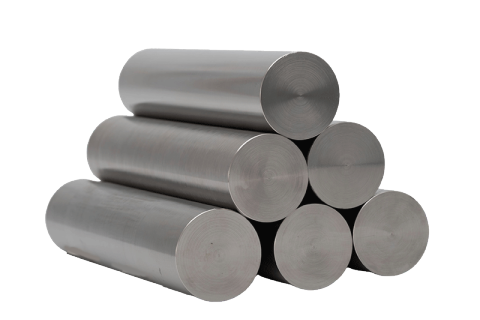

Under complex working conditions of high temperature, strong corrosion, and high wear, material selection directly determines the life and reliability of the equipment. Due to their comprehensive performance, cobalt-based high-temperature alloys have become "key materials" in the aerospace, energy, and chemical industries. This article analyzes cobalt-based alloys' applicable scenarios and alternatives based on industry technology trends and provides material selection references for industrial users.