- Home

- >

- News

- >

- Industry News

- >

News

Cobalt alloy is formed by cobalt and other alloying elements. It has excellent high-temperature, corrosion and wear resistance, with good comprehensive performance, and it is a metal material that can work in extreme environments for a longer time. Therefore, it is widely used in aerospace, oil and gas, power generation, food processing, steel industry, and other fields.

Cobalt alloy is widely utilized across various industries, owing to its superior properties such as excellent wear resistance, corrosion resistance, and high-temperature durability. This article primarily delineates the advantages of cobalt alloy compared to other alloys and its applications in different fields.

Cobalt alloy, while its name may not be widely recognized, plays an indispensable role in the field of modern engineering. Renowned for its outstanding wear resistance, corrosion resistance, and high-temperature performance, this alloy finds extensive applications across various industrial domains.

Cobalt alloys play a crucial role in the galvanizing industry. This article primarily discusses the specific products of Cobalt alloys in the galvanizing industry and the common components used in galvanizing industry.

Cobalt alloys are widely applied across various sectors of the petroleum industry. This article primarily discusses the advantages of cobalt alloys.

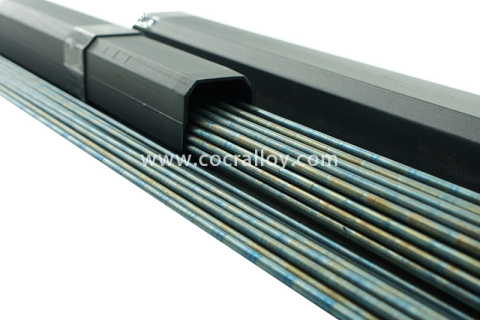

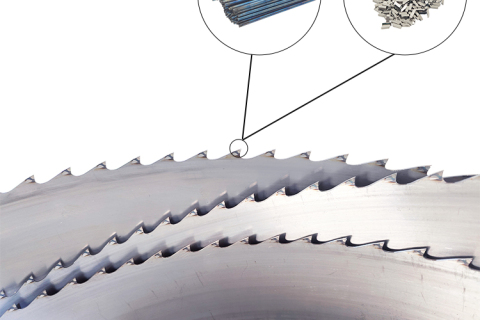

In the woodworking industry, the selection of the right materials is paramount for achieving precision and longevity. This article serves as a guide on "How to Choose Cobalt Products in the Woodworking Industry," shedding light on the considerations and applications of three common welding techniques.

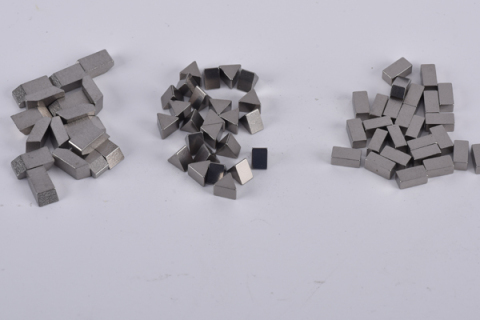

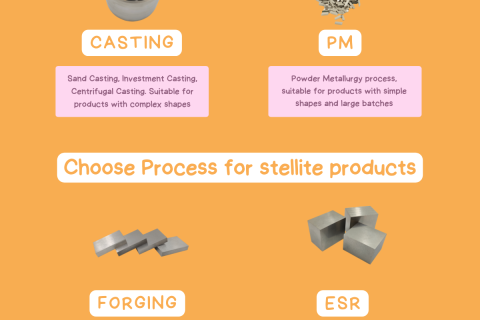

Cobalt alloy, celebrated for its remarkable properties, undergoes varied manufacturing processes. This comparison explores the nuances of casting, powder metallurgy, and other methods. From the robust cost-effectiveness of casting to the precision and strength of powder metallurgy, this exploration provides a concise overview of cobalt alloy production methods and their impact on diverse applications.

Welding Co 6 is a nuanced process that demands precision and expertise. AT SYTOP, we offer some insights into this intricate process.

Discover the essence of Cobalt Alloy and its versatile applications across industries. SYTOP, a leader in alloy manufacturing, sheds light on the unique properties of cobalt alloy and its indispensable role in various industrial settings.

SYTOP highlights the exceptional properties of Cobalt alloy1, emphasizing its wear, galling, and corrosion resistance, and its ability to retain these properties at high temperatures.

Shenyang Top New Material Co., Ltd. produces cobalt-based alloy spinner discs for glass wool production. These discs, known for their durability and high-temperature resistance, ensure optimal fiber formation.