News

When it comes to industrial machinery and applications, choosing the right bearing bush is crucial for ensuring longevity and performance. Bearing bushes are integral components that reduce friction between moving parts, providing smoother operation and reducing wear. As a leading bearing bush manufacturer, SYTOP is proud to offer a wide range of high-quality, wear-resistant bearing bushes designed to meet the demanding conditions of various industries.

Cobalt 12# Alloy is a cobalt-based alloy known for its outstanding wear, heat, and corrosion resistance. Ideal for industries requiring high durability, it excels in extreme environments.

In this article, we will explore what friction stir welding is, how it works, and the choice of tool material.

SYTOP is excited to announce our participation in the 15th Shanghai International Alloy Industry Expo 2024. We invite you to visit our booth and explore our premium cobalt alloy solutions designed for wear, corrosion, and high-temperature resistance.

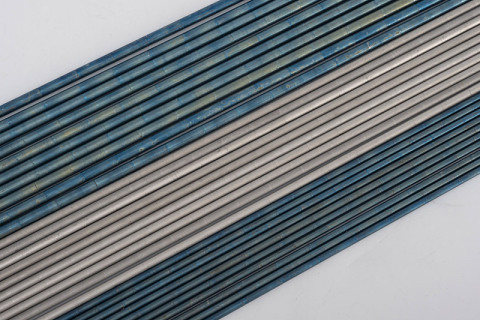

AWS A5.21 is a welding standard that governs bare rods and electrodes used for surface preparation. It defines chemical composition, mechanical properties, and guidelines for use. As a manufacturer of high-performance cobalt alloy welding rods, we produce cobalt alloy bare rods that comply with AWS A5.21, providing reliable products for extreme wear, corrosion, and heat-resistant applications.

Cobalt Alloy 25, known as Haynes 25, Alloy L605, and UNS R30605, is a high-performance alloy designed for extreme environments. This alloy is widely used in the aerospace and industrial sectors.

On November 22, 2024, SYTOP finished a new batch of transition pieces seals designed for GE turbines. These high-performance seals, made from cobalt-based alloys, provide reliable, long-lasting protection against leaks in critical turbine systems. The new seals are engineered to withstand high pressures and temperatures, ensuring GE turbines' optimal performance and longevity.

On November 21, 2024, SYTOP explored the critical differences between tungsten carbide and cobalt alloy in industrial applications. The comparison focuses on their material properties, wear resistance, temperature tolerance, and cost-effectiveness. This analysis is designed to help industries select the best material for their specific requirements, ensuring reliability and efficiency in challenging environments.

High-pressure homogenizer valves are critical components in various industrial processes, especially in food processing, chemical, and pharmaceutical industries, where stability and durability are essential. As a specialized manufacturer of cobalt alloys, we focus on producing high-quality, high-pressure homogenizer valve components that leverage the exceptional properties of cobalt alloys. Our products meet the industry’s demand for high-performance, highly reliable, and long-lasting parts. This article will explore the importance of high-pressure homogenizer valves, the advantages of cobalt alloy for these components, our production capabilities, and our custom services.Cobalt Alloy High-Pressure Homogenizer Valve Components