- Home

- >

News

2025/2/19, a Turkish customer sent an email, hoping that we could introduce the difference between our material and tungsten carbide. He said: "we use them in milk homogenization. original from german as tungstean carbide. can you recomend us your products much better tan tc mtrl?"

Under complex working conditions of high temperature, strong corrosion, and high wear, material selection directly determines the life and reliability of the equipment. Due to their comprehensive performance, cobalt-based high-temperature alloys have become "key materials" in the aerospace, energy, and chemical industries. This article analyzes cobalt-based alloys' applicable scenarios and alternatives based on industry technology trends and provides material selection references for industrial users.

On October 23, 2024, SYTOP introduced the innovative cobalt alloy thermowell U-795-22-1.4401+cobalt alloy 6 designed for power plant applications. This robust thermocouple protection tube features high-quality materials to withstand extreme conditions, ensuring reliable performance in environments with high-speed coal dust.

When selecting materials for high-performance applications, cobalt alloys and 316L stainless steel are two options that are often considered. Both materials offer unique advantages but excel in different environments and applications. In this article, we compare the properties of cobalt alloys and 316L to help you understand which material is best for your needs.

Cobalt alloys are widely used in industries requiring wear and corrosion resistance materials. Cobalt alloys are an excellent solution for demanding applications especially in high temperatures, known for their exceptional durability, wear resistance, and ability to withstand extreme temperatures.

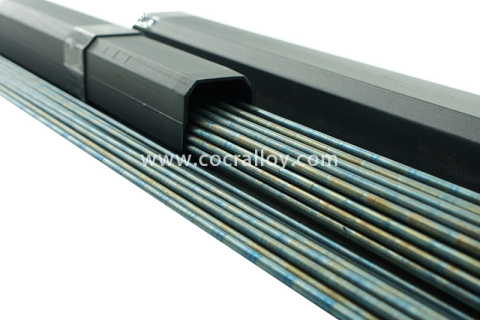

This News highlighted the advantages of cobalt alloy overlay welding in extending the lifespan of components under extreme working conditions. The technique ensures wear, corrosion, and high-temperature resistance, making it ideal for various industries.

In September 2024, SYTOP prepared to ship another batch of our long-standing cobalt alloy propellers, designed for use in hot-dip galvanizing production lines. These propellers, known for their exceptional wear resistance, high-temperature endurance, and corrosion protection, continue to support the demanding needs of galvanizing processes worldwide.

Cobalt-based superalloys show superior properties than other materials in strength, elasticity, and many other aspects. Let us explore cobalt-based superalloys and understand what they are, their classifications, and where they can be applied.

Cobalt alloy is formed by cobalt and other alloying elements. It has excellent high-temperature, corrosion and wear resistance, with good comprehensive performance, and it is a metal material that can work in extreme environments for a longer time. Therefore, it is widely used in aerospace, oil and gas, power generation, food processing, steel industry, and other fields.

Cobalt alloy is widely utilized across various industries, owing to its superior properties such as excellent wear resistance, corrosion resistance, and high-temperature durability. This article primarily delineates the advantages of cobalt alloy compared to other alloys and its applications in different fields.

Cobalt alloys play a crucial role in the galvanizing industry. This article primarily discusses the specific products of Cobalt alloys in the galvanizing industry and the common components used in galvanizing industry.

SYTOP recently received customers from Turkey for a factory audit on November 3, 2023, and learned how we produce cobalt alloy glass wool spinner discs.