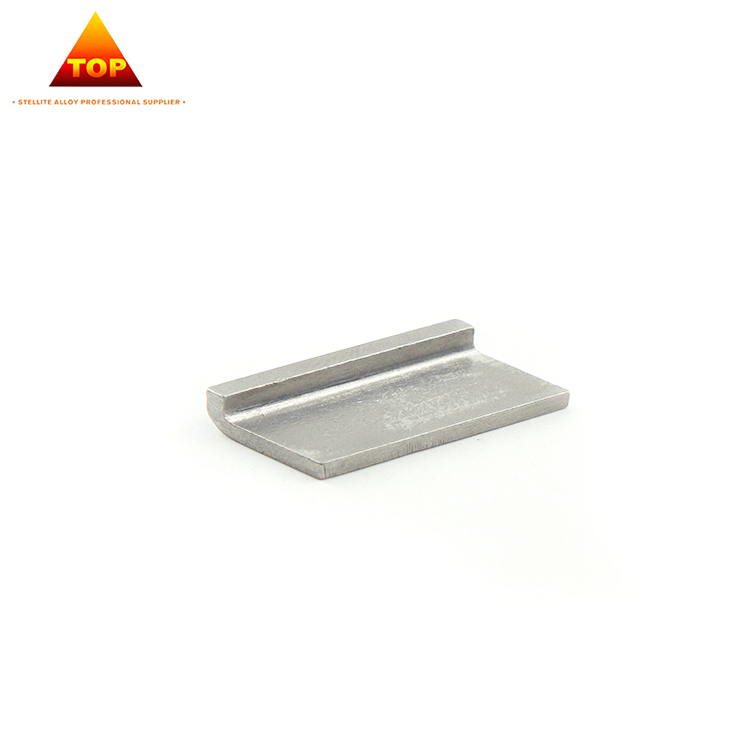

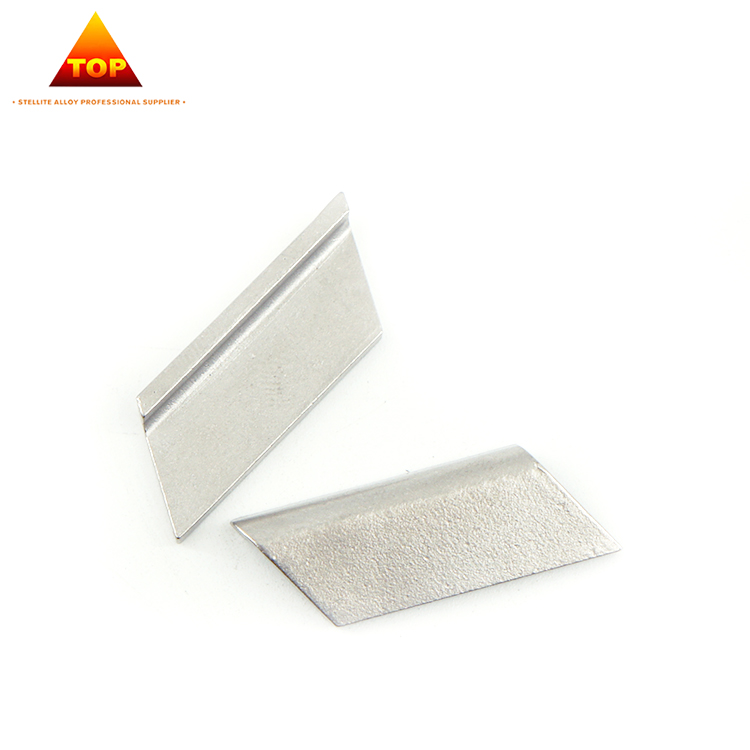

Cobalt Alloy Steam Erosion Shields For Steam Turbine Blade

The last stage blades of the steam turbine are prone to water corrosion, and the failure of the blades leads to the unsafe operation of the steam turbine. The blade anti-corrosion sheet properly solves the problem, and the cobalt alloy anti-corrosion sheet is welded to the blades by brazing, effectively prevent the water corrosion of the steam turbine blades, and improve the safety and economy of the normal operation of the steam turbine.

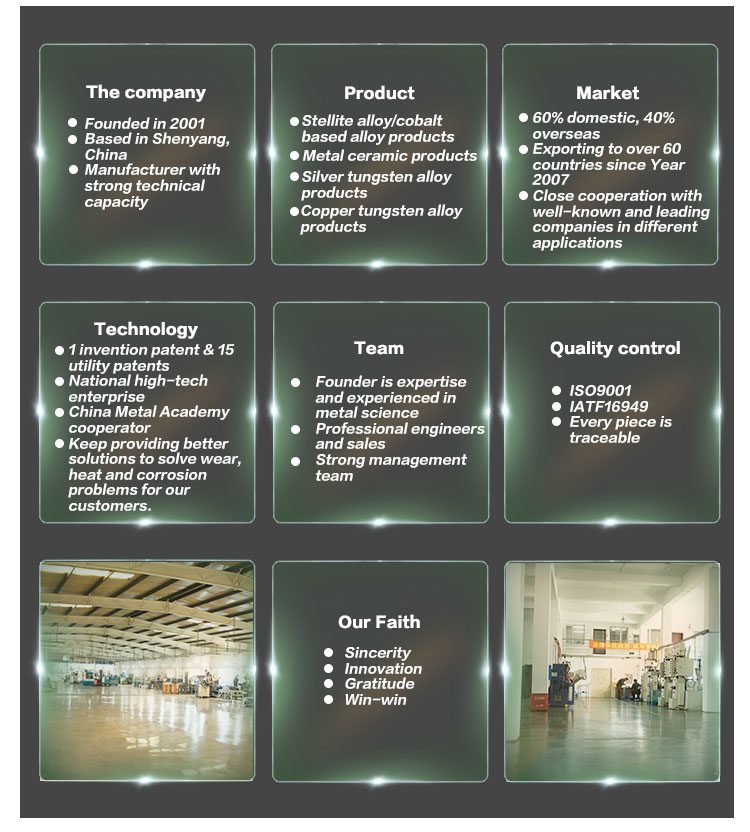

- SYTOP

- China

- 20-35days

- 3000pcs/ month

- Information

- Video

Cobalt Alloy Steam Erosion Shields For Steam Turbine Blades

Cobalt alloy strips or shields can be used to protect cobalt alloy turbine blades from damage due to erosion, corrosion, and other wear and tear. Cobalt-based alloy is known for its hightemperature resistance, wear resistance and corrosion resistance, which makes it an ideal material for use in turbine blades.

Cobalt alloy strips or shields can be applied to the leading edge or other critical areas of the turbine blade to provide additional protection against wear and tear. These strips or shields are typically made from a thin layer of cobalt alloy that is applied to the surface of the blade using a welding or brazing process. The thickness and location of the strips or shields will depend on the specific design of the turbine blade and the operating conditions it will be subjected to.

1. Cobalt alloys strips have higher melting points than nickel (or iron) alloys ,This gives them the ability to absorb stress to a higher absolute temperature .

2. Cobalt alloys strips give superior hot corrosion resistance to gas turbine atmospheres , this is due to their high chromium content.

3. Cobalt alloys strips show superior thermal fatigue resistance and weldability over nickel alloys .

---Excellent wear and corrosion resistance even at high temperature up to 800℃

Chemical compositions and properties (%)

Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density (g/cm3) | Hardness (HRC) |

Cobalt Alloy 3 | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 | |

Cobalt Alloy 6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

Cobalt Alloy 12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 | |

Cobalt Alloy 20 | 2.2-3.0 | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.05 | ≤0.05 | 8.65 | 53-59 | |

Cobalt Alloy T 400 | 0.04 | 2.5-2.7 | 8-10 | 27-29 | Bal. | 55 | |||||||

Cobalt Alloy T 800 | 0.04 | 3.2-3.6 | 16-18 | 27-29 | Bal. | 58 |

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

We offer a wide range of cobalt alloy products with various brands and shapes to meet the needs of our customers. Whether you require standard Cobalt alloy products or custom-designed parts, we can supply. Our Cobalt alloy products are known for their excellent wear resistance, corrosion resistance, and high-temperature stability, making them an ideal choice for a variety of applications, such as aerospace, automotive, and industrial manufacturing.

More details about cobalt chrome round bar please do not hesitate to contact me .