ST Tipped Band Saw Blades

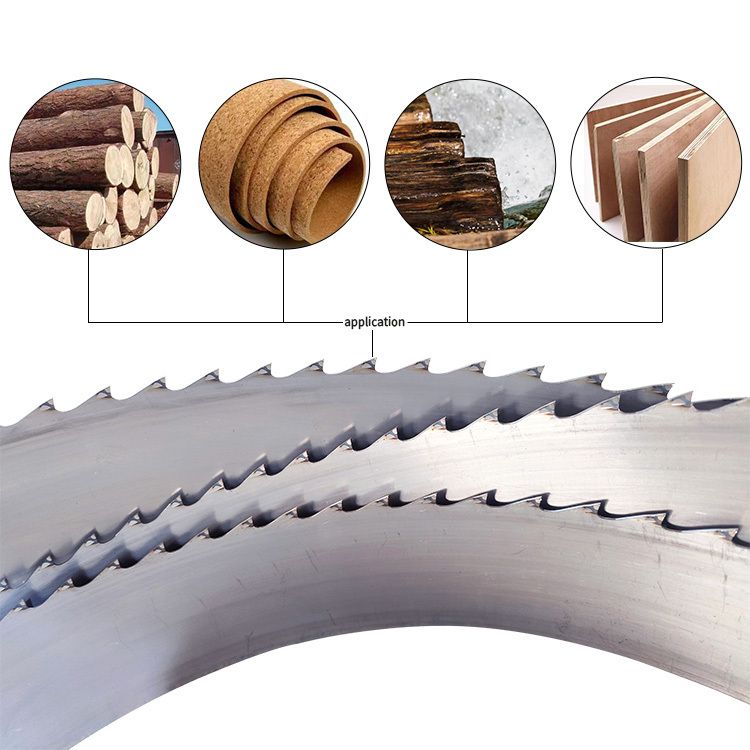

ST tipped band saw blades are widely used in the woodworking industry. Our band saw blades are welded with cabalt alloy saw teeth, and their performance is more outstanding when dealing with soft wood, frozen wood, hard miscellaneous wood and wood containing corrosive medium.

- SYTOP

- China

- 2 weeks

- 5000kgs+/month

- Information

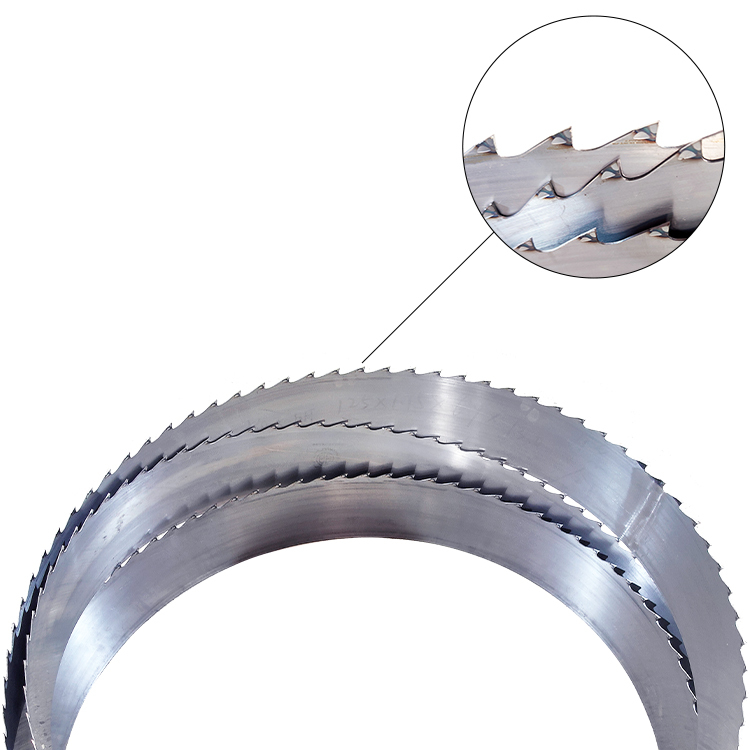

ST(cobalt alloy) Tipped Band Saw Blades

The cobalt alloy tipped Bandsaw Blades are engineered for precision and durability. Utilizing the inherent properties of cobalt alloy, these blades offer consistent performance across diverse cutting applications.

Material Composition: Teeth constructed from cobalt based alloy, recognized for its wear resistance, corrosion resistance, and thermal stability.

Design Precision: The blades are designed for accuracy, ensuring consistent cuts across various materials.

Application Range: Suitable for diverse cutting tasks, from soft wood to frozen wood.

Edge Retention: The CoCrW composition ensures prolonged edge retention, minimizing the frequency of maintenance or replacement.

ST(cobalt alloy) tipped Bandsaw Blades are engineered for optimal cutting performance. Balancing hardness and flexibility, they address complex cutting challenges efficiently. Their design ensures consistent cuts, making them suitable for both hardwood, frozen wood and wood containing corrosive medium.

Specifications

Customize is available.

| Width(mm) | Thickness(mm) | Length(m) |

| 80-260 | 1.0-2.0 | 4-10 |

Some Processing Processes Show

Grinding the weld

Clean and polish the excess burrs and overflow welding slag after the band saw butt welding, and form a smooth butt joint surface between the saw blades.

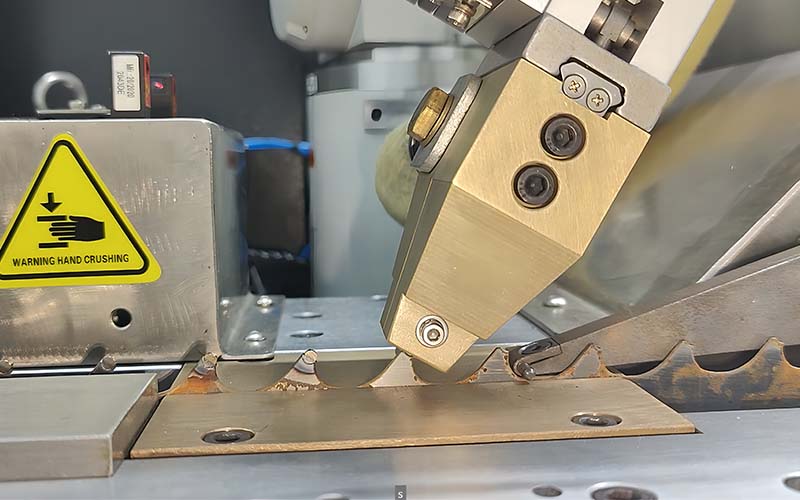

Welding teeth

The Cobalt alloy tipped band saw blade uses resistance welding technology to weld the cobalt sawtooth to the strip steel. Good stress treatment technology ensures that the saw blade is not easily deformed during high-speed operation, and greatly reduces the probability of tooth loss.

Gringding saw teeth

Sharpen the front corner, rear corner, and both sides of the Carbide band saw blade to obtain an extremely thin saw kerf. For extremely high woodworking requirements, from coniferous and hardwood to harder wood species

Rooling

In order to make the saw blade flat against the saw wheel as a whole, roll out the tension of the saw blade to eliminate the internal stress of the saw blade. Enables a precise fit between the band saw blade and band saw machine to cut hard and soft woods in a resource-optimized manner.

For detailed information or inquiries regarding the cobalt alloy tipped Bandsaw Blades, please contact us.