AWS ERCoCr-C Co 1 welding rods

AWS ERCoCr-C Co 1 Welding Rods are made from premium cobalt-based alloy ST1 and excel in providing exceptional strength, corrosion resistance, and heat tolerance. Designed to meet AWS standards, they ensure consistent and durable welds, even in challenging environments.

- TNM

- China

- 1 week

- 5000kgs+/month

- Information

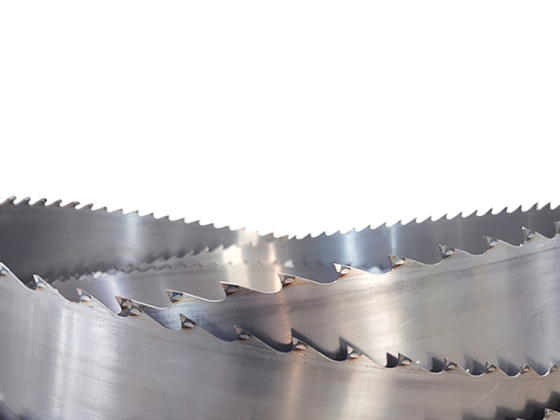

AWS ERCoCr-C Co 1 welding rods Casting Bare Rods

Cobalt alloy grade 1 casting bare rods is AWS 5.21 ErCoCr-C

ST 1 Welding Rods are cobalt-based alloy rods, specifically designed for hard-facing surfacing. They meet the AWS 5.21 ErCoCr-C standard.

Cobalt Welding Rod is supplied in the following forms:

As-Cast: Meets most hardfacing requirements.

Densified: Hipped to eliminate centerline porosity.

Ground/Finished: Eliminates surface imperfections.

Applicable Processes:

Oxy-Acetylen Tungsten Inert Arc (TIG)

Standard rod diameters include:

2.7 mm

3.2 mm

4.0 mm

4.8 mm

5.0 mm

6.0 mm

6.4 mm

Note: Additional diameters, rod lengths(normally length is 1m), and packaging available upon request.

Advantages of cobalt alloy welding rods:

Produced by horizontal continuous casting.

Excellent surfacing performance.

Has good high temperature strength and good wear resistance, high-temperature resistance, impact resistance and certain corrosion resistance.

Applications:

Argon arc welding, oxyacetylene welding, etc.

It can be used for surface treatment of parts and components in extrusion dies, turbine blades, exhaust valves of internal combustion engines, oil drilling tools, marine engineering, petroleum industry, coal, oil refining, chemical engineering, boilers and other industries.

Chemical compositions and properties (%)

| Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | Hardness(HRC) |

| ST 1 | 2.2-2.8 | - | ≤2.0 | 29.0-33.0 | ≤3.0 | ≤1.0 | 11.0-14.0 | Bal. | ≤3.0 | 51-55 |

| ST 6 | 0.9-1.4 | 1.0 | ≤1.5 | 27.0-31.0 | ≤3.0 | ≤1.5 | 3.5-5.5 | Bal. | ≤3.0 | 38-44 |

| ST 12 | 1.1-1.7 | 1.0 | ≤1.0 | 28.0-32.0 | ≤3.0 | - | 7.0-9.5 | Bal. | ≤3.0 | 44-49 |

| ST 21 | 2.0-3.0 | 1.0 | ≤1.0 | 25.0-39.0 | 1.75-3.75 | 5.0-6.0 | - | Bal. | ≤3.0 | 56-60 |

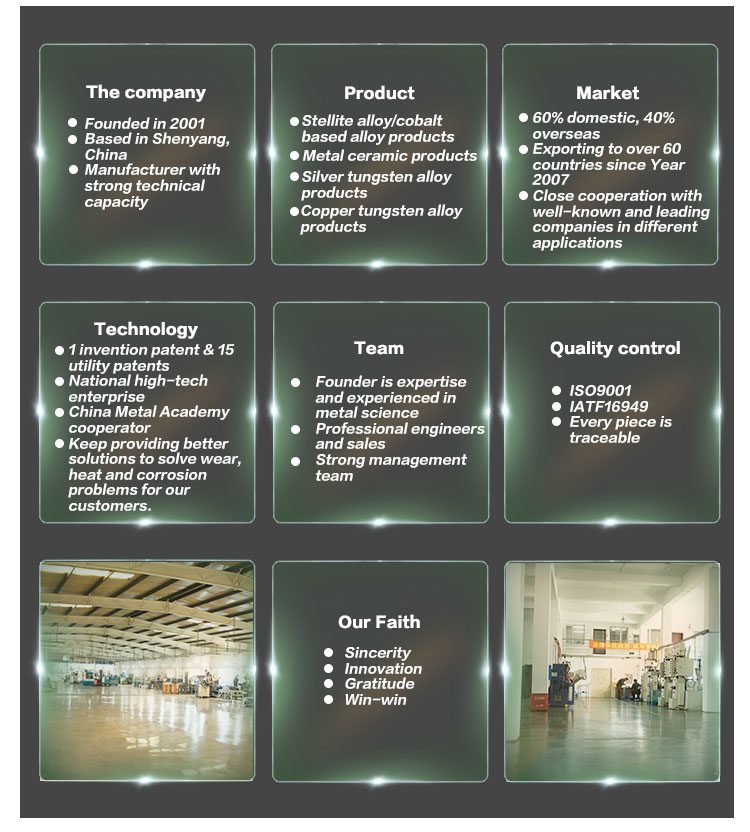

SYTOP cobalt-based alloy is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Most of our products are made upon request so contact us right now for personal and professoinal service.