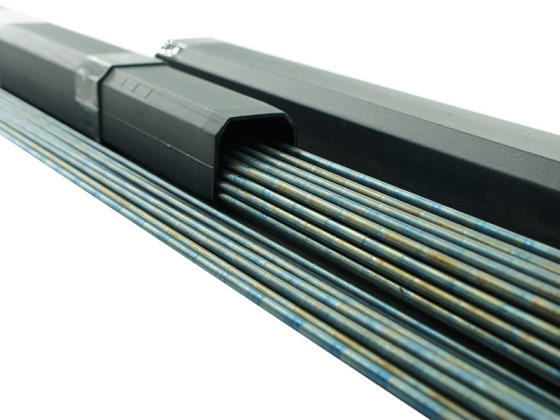

Cobalt Alloy 12 and H13 extrusion die

Cobalt Alloy extrusion dies for continuous extrusion of copper and aluminum in hot extrusion. We can supply the cobalt alloy extrusion die core, and we can also provide integral extrusion die. ST 12 and H13 are combined by hot charging, etc., hope to reduce production costs for you.

- TNM

- China

- 30days

- 10000PCS /MONTH

- Information

Extrusion is a metal forming process , in which billet is passed through a die , to get required cross section of component .

Non cutting process

Production of Fixed cross section

Types of extrusion process

Direct extrusion process

Indirect extrusion process

Impact extrusion process

Hydrostatic extrusion process

Tube extrusion process

Extrusion die is a very important part no matter which process you use , that is the Extrusion die . Also the extrusion die’s quality will effect the production cost and efficient directly .

We are professional manufacturer who supply cold extruding and cold stretch stainless steel extrusion die material and hot extruding copper and Aluminum extrusion die material . SYTOP is focused on producing high quality extrusion die , increase the life span of extrusion die and improve the production efficient .

There are several material could be selected , NiCr-Ti metal ceramic and Cobalt Chrome Alloy , we also could supply the integral extrusion die , such as metal ceramic inlay Hot work tool steel , Cobalt Chrome Alloy inlay Hot work tool steel . we hope to decrease the production cost for you .

Application:

1. NiCr-TiC is fit for the cold extruding and cold stretch stainless steel

2. Cobalt alloy is fit for hot continuous extruding copper and Aluminum.

Material for reference .

Material | Grade | Hardness (HRC ) | Density ( g/cm3) |

NiCr- TiC | TiC 30 | 50-53 |

6.1-6.5 g/cm3 |

TiC 35 | 53-56 | ||

TiC 40 | 56-59 | ||

TiC 45 | 59-63 | ||

TiC 50 | 63-67 | ||

TiC 55 | 68-71 | ||

Cobalt alloy

| Co 3 | 51-58 | 8.55 g/cm3 |

Co 12 | 47-51 | 8.4 g/cm3 |

Advantage :

1. The ceramic extrusion die do not have any adhesion with the extruded part.

2. Long life span, metal ceramic die is 4-6 times longer than the carbide tungsten dies.

3. The price is cheaper than carbide tungsten and deduct the production cost for you .