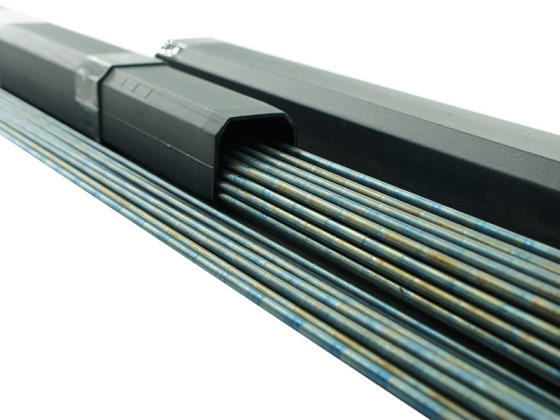

Coballt Alloy 12 Cylindrical Saw Teeth for Bandsaw Blade

Cylindrical saw teeth for bandsaw blades are typically made of cobalt alloy 12 because of its excellent wear resistance and toughness. These saw teeth are designed to cut wood. We produce it by powder metallurgy process with high quality, and the product quality is stable.

- TNM

- China

- 4 weeks

- 5000kgs+/month

- Information

Cobalt Alloy 12 Cylindrical Saw Teeth for Bandsaw Blade

Cobalt Alloy 12 is a cobalt based alloy with high temperature resistance, wear resistance, and corrosion resistance. This cobalt-chromium alloy is particularly well-suited for that require both high-temperature and high-abrasion resistance at the same time. Its outstanding properties make it a popular choice for a wide range of industrial applications, including cutting tools, saw blades, valve components, and other components that need to withstand harsh environments and severe operating conditions.

When manufacturing cobalt alloy 12 cylindrical saw teeth for bandsaw blades, the alloy is typically produced by powder metallurgy process. This kind of saw teeth are highly durable and can withstand the high stresses and temperatures associated with cutting operations. They are also resistant to corrosion and can maintain their sharpness over a longer time compared to other materials, such as high-speed steel.

(1). Cobalt Alloy 12 could be considered an intermediate alloy .

(2). It contains a higher fraction of hard, brittle carbides than Cobalt 6

(3).It has increased resistance to low angle erosion, abrasion, and severe sliding wear while stretaining reasonable impact and cavitation resistance.

(4). Cobalt Alloy 12 is often used self-mated or running against .

What is the Details of our cobalt alloy saw tips ?

Material : | Cobalt Alloy 12 |

Process : | Powder Metallurgy , it is short for PM |

Hardness: | 44-49HRC |

Density : | 8.5g/cm ³ |

Size : | Triangle , rectangle and profiled , customized-made is also available |

Properties : | Wear and corrosion resistance |

Application : | Cobalt Chrome Alloy is also more resistant to the abrasive acids found in some woods like red cedar. |

Instructions : | The Cobalt Chrome Alloy Tipped saws, have a tip welded directly to the saw tooth |

Usage : | Welding on Circular saw and Band saws teeth to cut woods |

Tolerance control : | Surface polishing and tolerance ±0.003”/±0.005” (±0.0762/±0.127mm ) |

Production lead time | Samples 7 days , normal order 10-25 days |

Production capacity : | 1000,000pcs one month. |

Package : | 1000pcs in 1 plastic bag and put in 1 plastic keg |

Cobalt Chrome Alloy tipped saws have shown to be able to:

•Increase run times.

•Cut with thinner kerf.

•Produce a smoother sawn surface.

•Reduce sawing variations - Better cutting accuracy. (allowing for tighter target sizes)

•Reduce the power consumption during cutting.

•Reduce the cutting downtime for saw changes and saw maintenance.

•Increased saw life due to the ability to achieve more sharpening and at longer intervals.

Cobalt Chrome Alloy is also more resistant to the abrasive acids found in some woods like red cedar.

This allows the tips to stay sharp longer than carbide tips and significantly longer

than swaged saw steel when cutting unseasoned woods.

We have produced more than 100 kinds of specifications tips and export to Canada, USA,

France, New Zealand, Australia, Norway and Russia etc. more than 40 countries and areas.

Which size do you supply ?

We can manufacture Saw tips according to your drawings and demands. We can produce rectangular, triangle, specical-shaped saw tips .and we also can manufacture saw tips of U.S.A. standard and Europe standard

Application:

ST 12 saw tips are commonly used in the production of woodworking saw blades, where they are used to cut hard and dense wood.

Welding on Circular saws and Band saws as teeth to cut woods

Cobalt ALloys' Other Application.

Metal: Cobalt Alloy is also used in metal extrusion applications, including the extrusion of aluminum and copper.

Plastics: Cobalt Based Alloy is compatible with some plastics, making it a good choice for saw blades that need to cut plastic materials.

Composites: Cobalt alloy is also commonly used in the cutting of composite materials, including fiberglass, carbon fiber, and Lyocell.

Send your inquiry details to us for free samples and best price now !