Haynes 25 L605 Seals for Turbine

Haynes 25/L605 is a Cobalt-Nickel-Chromium-Tungsten alloy that combines good high-temperature strength with good resistance to oxidizing environments up to 980°C (1795°F) for long exposures. Some of the industries Haynes 25/L605 is supplied to include aerospace, power generation, electronics, land-based turbines and medical.

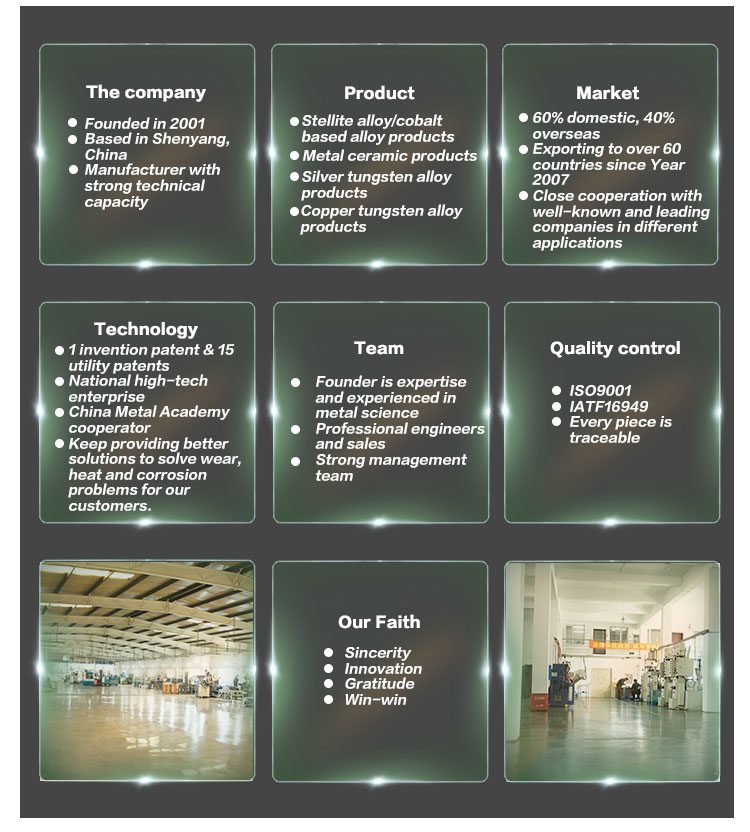

- SYTOP

- China

- 50-60days

- 3000pcs/ month

- Information

Haynes 25 L605 Seals for Turbine

Alloy L-605 / Haynes 25 has many applications in military and commercial gas turbine engine components such as rings, blades and combustion chamber parts.

---Excellent wear and corrosion resistance even at high temperature up to 900℃

Chemical compositions and properties (%)

Brand | C | Mn | Si | Cr | Ni | W | Co | Fe | P | S |

L605 | 0.05-0.15 | 1.0-2.0 | 0.4Max | 19-21 | 9-11 | 14-16 | Bal. | 3.0max | ≤0.04 | ≤0.03 |

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, power, automotive, paper and food processing industry etc.

Specifications that we can made :

Different size bars , rods , ingots , plate

Drawing made seal , valve seat and ball , bush and sleeve etc.

Some size tube

Most of our products are made upon request so contact us right now for personal and professoinal service.

More details about cobalt chrome round bar please do not hesitate to contact me .