- Home

- >

- Cocr Spinner

- >

Cocr Spinner

Our CoCr Spinners, an integral component in the glass wool industry, are known for their robustness and longevity.

- TNM

- China

- 30-60days

- 1000pcs /month

- Information

Our CoCr Spinners, an integral component in the glass wool industry, are known for their robustness and longevity.

What is the Details of Cobalt Alloy CoCr Spinner disc?

Material : | Cobalt and nickel base alloy |

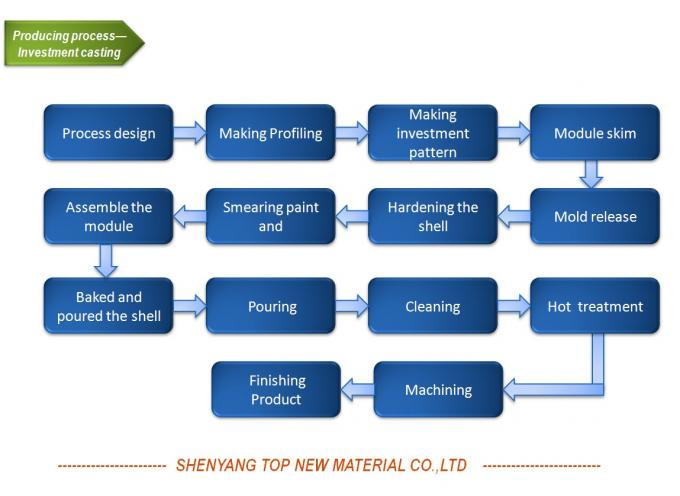

Process : | Investment castings |

Application : | Glass wool industry |

Density : | 8.4 g/cm ³ |

Overall dimensions : | φ200~500mm

|

Hole dimensions: | φ0.5~1.0mm |

Holes amount: | 7000~33000 units |

Operating temperature: | 1050°C |

Rotating speed: | ≤3000 r/min |

Tolerance control : | grinding surface , tolerance upon drawing |

Fiber dimensions: | ≤7μm |

Lifetime: | ≥168 hours |

Package : | carton or wooden case , pallet for export |

Dimensions: Available in diameters ranging from φ200 to 500mm.

Durability: Proven to perform optimally for at least 168 hours of continuous operation.

Chemical Components & Physical Properties

Grade NO. | Chemical Components | Physical Properties | ||

Density (G/cm3)≥ | Hardness HRC≥ | Elongation Mpa≥ | ||

TPM10 | C CR NI W 0.4 30 50 15 | 8.3 | 35 | 700 |

2.4879 | C CR NI W Fe 0.4 28 48 5 Bal. | 8.3 | 400 | |

CoCrW31 | C CR NI W Co 0.5 26 1 0.5 7.5 Bal. | 8.5 | 32 | 735 |

Material Excellence: Crafted from a unique blend of cobalt and nickel-based alloys.

Precision Engineering: Produced through investment casting for dimensional accuracy and superior finish.

Performance: Exceptional operational efficiency at temperatures up to 1050°C.

Production process

Service Commitment

"We provide comprehensive support, from initial design to production, ensuring your specifications are met with precision. Our team is dedicated to offering solutions that drive your operational success."