Cobalt Chrome Centrifugal Spinner Disc

Optimize your glass wool production with our high-precision Glass Wool Spinners, designed for consistent performance and unparalleled reliability.

- TNM

- China

- 30-60days

- 1000pcs /month

- Information

Optimize your glass wool production with our high-precision Glass Wool Spinners, designed for consistent performance and unparalleled reliability.

What is the Details of our Cobalt Chrome Centrifugal Spinner Disc?

Material : | Cobalt and nickel base alloy |

Process : | Investment castings |

Application : | Glass wool industry |

Density : | 8.4 g/cm ³ |

Overall dimensions : | φ200~500mm

|

Hole dimensions: | φ0.5~1.0mm |

Holes amount: | 7000~33000 units |

Operating temperature: | 1050°C |

Rotating speed: | ≤3000 r/min |

Tolerance control : | grinding surface , tolerance upon drawing |

Fiber dimensions: | ≤7μm |

Lifetime: | ≥168 hours |

Package : | carton or wooden case , pallet for export |

Chemical Components & Physical Properties

Grade NO. | Chemical Components | Physical Properties | ||

Density (G/cm3)≥ | Hardness HRC≥ | Elongation Mpa≥ | ||

TPM10 | C CR NI W 0.4 30 50 15 | 8.3 | 35 | 700 |

2.4879 | C CR NI W Fe 0.4 28 48 5 Bal. | 8.3 | 400 | |

CoCrW31 | C CR NI W Co 0.5 26 1 0.5 7.5 Bal. | 8.5 | 32 | 735 |

Advanced Material: Utilizes a sophisticated cobalt and nickel base alloy for enhanced durability.

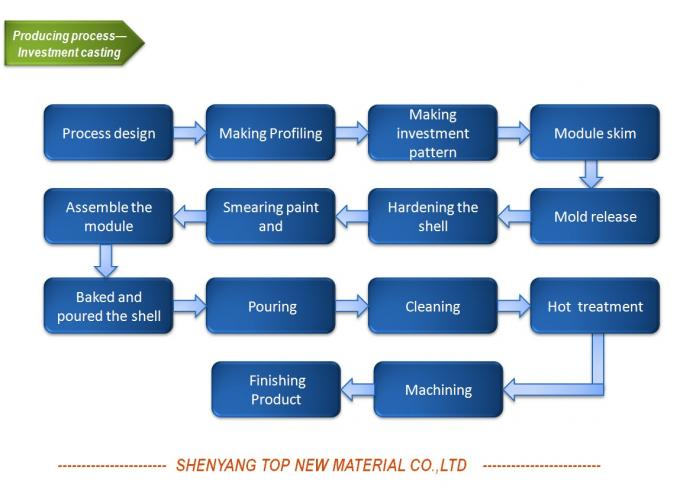

Manufacturing Process: Precision-formed through investment casting techniques.

High-Temperature Suitability: Capable of withstanding operating environments of up to 1050°C.

Production process

Application :

From custom design solutions to ongoing project support, our team is committed to ensuring your complete satisfaction and project success. We respond promptly with professional solutions tailored to your needs.