- Home

- >

News

AWS A5.21 is a welding standard that governs bare rods and electrodes used for surface preparation. It defines chemical composition, mechanical properties, and guidelines for use. As a manufacturer of high-performance cobalt alloy welding rods, we produce cobalt alloy bare rods that comply with AWS A5.21, providing reliable products for extreme wear, corrosion, and heat-resistant applications.

Cobalt-based superalloys show superior properties than other materials in strength, elasticity, and many other aspects. Let us explore cobalt-based superalloys and understand what they are, their classifications, and where they can be applied.

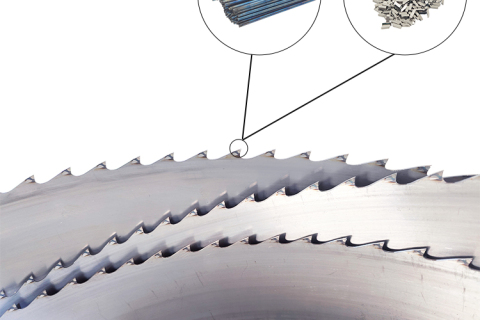

In the woodworking industry, the selection of the right materials is paramount for achieving precision and longevity. This article serves as a guide on "How to Choose Cobalt Products in the Woodworking Industry," shedding light on the considerations and applications of three common welding techniques.

Our innovative cobalt welding rods were showcased at LIGNA 2023, garnering high praise. Hosted in Hannover, Germany on May 15th-19th, the event witnessed numerous on-site transactions and product giveaways.

May 15th to May 19th, 2023, Hall 15, 77/2. LIGNA is one of the most important trade shows for the woodworking and wood processing industry and it is scheduled to take place in Hannover.

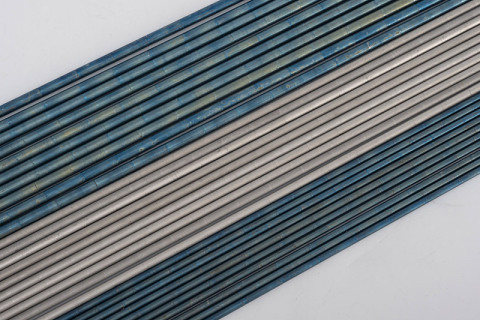

ERCoCr welding rod bonds well with stainless and other weldable alloy steels. Certification to AWS specification – A5.21 ERCoCr-A for bare rod; A5.13 ECoCr-A for the coated electrode.