Cobalt Chrome Alloy Cobalt Alloy 12 Saw Tips CWF Series

Cobalt Chrome Alloy

- Cobalt Chrome Alloy

- China

- within 20 days

- 1 million/ month

- Information

Cobalt Chrome Alloy 12 Saw tips advantages

(1). Cobalt Alloy 12 could be considered an intermediate alloy .

(2). It contains a higher fraction of hard, brittle carbides than Cobalt Alloy 6

(3).It has increased resistance to low angle erosion, abrasion, and severe sliding wear while stretaining reasonable impact and cavitation resistance.

(4). Cobalt Alloy 12 is often used self-mated or running against .

What is the Details of our cobalt alloy 12 saw tips ?

Material : | Cobalt Alloy 12 |

Process : | Powder Metallurgy , it is short for PM |

Hardness: | 44-49HRC |

Density : | 8.5g/cm ³ |

Size : | Triangle , rectangle and profiled , customized-made is also available |

Properties : | Wear and corrosion resistance |

Application : | Cobalt Chrome Alloy is also more resistant to the abrasive acids found in some woods like red cedar. |

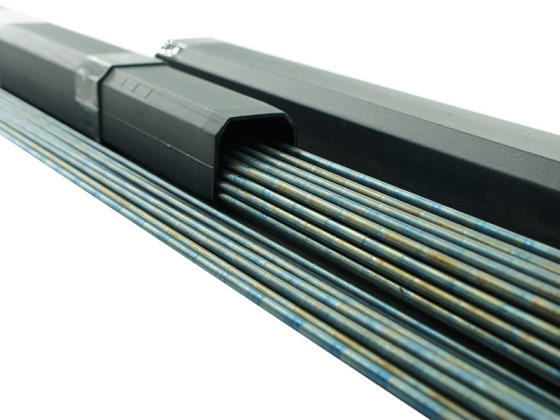

Instructions : | The Cobalt Chrome Alloy Tipped saws, have a tip welded directly to the saw tooth |

Usage : | Welding on Circular saw and Band saws teeth to cut woods |

Tolerance control : | Surface polishing and tolerance ±0.003”/±0.005” (±0.0762/±0.127mm ) |

Production lead time | Samples 7 days , normal order 10-25 days |

Production capacity : | 1000,000pcs one month. |

Package : | 1000pcs in 1 plastic bag and put in 1 plastic keg |

Cobalt Chrome Alloy tipped saws have shown to be able to:

Increase run times.

Cut with thinner kerf.

Produce a smoother sawn surface.

Reduce sawing variations - Better cutting accuracy. (allowing for tighter target sizes)

Reduce the power consumption during cutting.

Reduce the cutting downtime for saw changes and saw maintenance.

Increased saw life due to the ability to achieve more sharpening and at longer intervals.

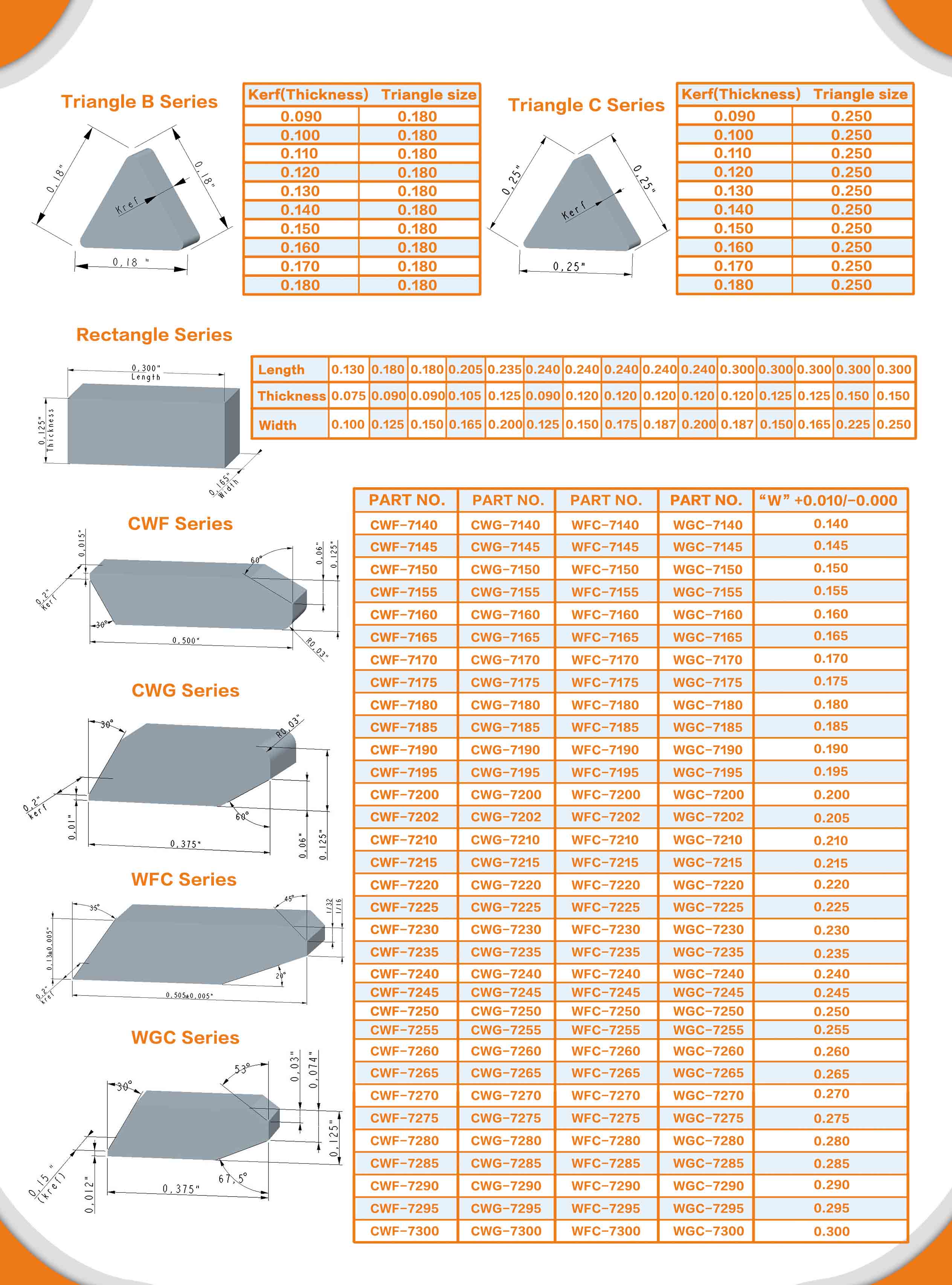

The Difference Between CWF and CWG Series

CWF stands for "Cant, Wedge, and Flitch" and is specifically engineered for cutting hardwood logs, as well as frozen or abrasive wood. The tooth profile of CWF saw teeth is optimized for cutting efficiency and longevity in these types of logs.

On the other hand, CWG stands for "Cant, Wedge, and Grade" and is designed for cutting softwood logs. The tooth profile of CWG saw teeth is optimized for cutting speed and cleanliness, as softwood logs are typically easier to cut than hardwood logs.

Cobalt Chrome Alloy is also more resistant to the abrasive acids found in some woods like red cedar.

This allows the tips to stay sharp longer than carbide tips and significantly longer

than swaged saw steel when cutting unseasoned woods.

We have produced more than 100 kinds of specifications tips and export to Canada, USA,

France, New Zealand, Australia, Norway and Russia etc. more than 40 countries and areas.

Which size do you supply ?

We can manufacture Saw tips according to your drawings and demands. We can produce rectangular, triangle, specical-shaped saw tips .and we also can manufacture saw tips of U.S.A. standard and Europe standard

Application:

Welding on Circular saw and Band saws teeth to cut woods

Send your inquiry details to us for free samples and best price now !