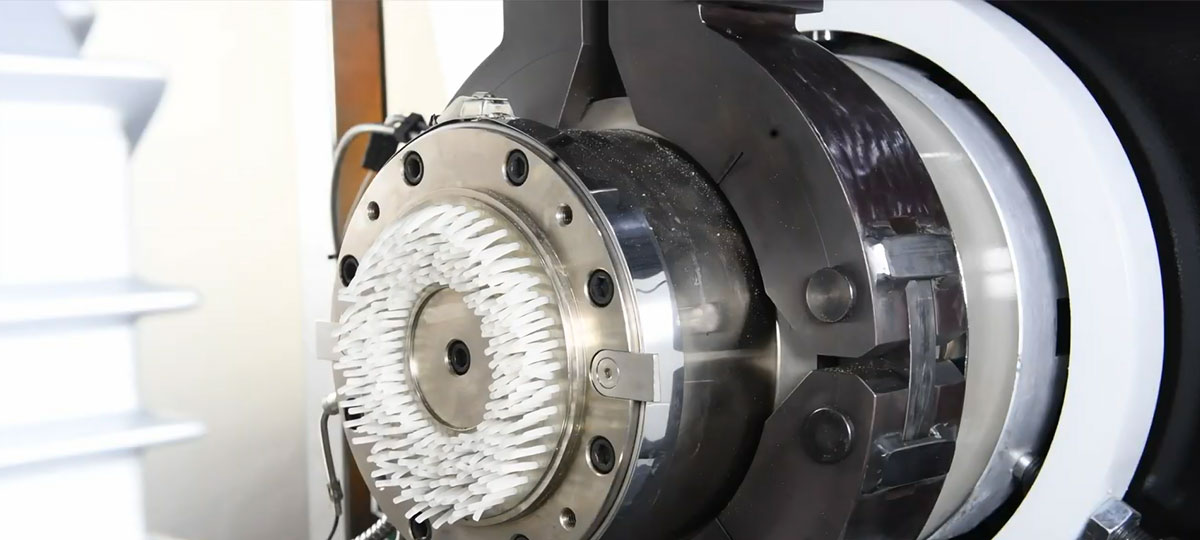

Underwater Pelletizer knife

The underwater pelletizer knife ensures precise and efficient cutting of polymer strands into uniform pellets. Its durable construction and optimal sharpness guarantee consistent performance, reducing downtime and maintenance costs.

- SYTOP

- China

- 20-30days

- 2000pcs/month

- Information

Underwater pelletizing knife: a precise and efficient solution for polymer production

Product Overview

The underwater pelletizing knife is a precision tool designed for polymer production. Its core function is to quickly and accurately cut molten polymer strips into uniform pellets. This tool occupies an important position in the polymer processing industry with its excellent cutting performance, efficient production capacity and durability.

Core Features

Precise cutting: Made of high-quality materials, the blade is sharp and durable, ensuring that every cut can produce pellets of regular shape and uniform size, thereby improving the overall quality of the product.

Efficient production: Designed for large-scale production environments, it has excellent continuous operation capabilities. Its structure is easy to replace quickly, effectively reducing downtime caused by knife changes and improving overall production efficiency.

Durable and reliable: The underwater pelletizing knife has a sturdy structure and can withstand harsh conditions such as high temperature and high pressure in the polymer production process, extending its service life and reducing maintenance costs.

Application scenarios

Underwater pelletizing knives are widely used in production lines of polymer materials such as plastics, rubber, and chemical fibers, especially in situations where high-precision and high-efficiency cutting is required. Whether it is injection molding, extrusion or blow molding, it can be seen.

The underwater pelletizing knife is an indispensable key component in the field of polymer production. It provides manufacturers with stable production guarantees with precise cutting, efficient production and reliable durability. Choosing an underwater pelletizing knife means choosing higher production efficiency, lower production costs and better product quality.

Why Choose Shenyang Top New Material Co., Ltd As your Sipplier?

With the experience gained of producing over 5,000 metal alloy products, we are able to provide you with high temperature wear and corrosion resistant solutions!

Two decades of expertise in Stellite Alloys production, only focus on Cobalt Alloys

Innovative R&D with exclusive powder metallurgy technology, collaborations with many research institutions

Dedicated technical support throughout every sales process

Explore Infinite Possibilities with Our Advanced Technology and Custom Cobalt Alloys

Customized products according to your drawings

Customize or recommend suitable stellite alloys grades according to different needs

If there are no drawings, we will measure your samples and give you a drawing for free.

Inspection of Whole Process to Ensure High Quality

Real-time inspection of production: To ensure that the production sequence of the product obeys the specifications, and the parts are not damaged

Full factory inspection: Each batch of products from SYTOP will undergo a strict chemical, density and hardness inspection

Loading safety inspection: To ensure the safety of the goods in the shipping