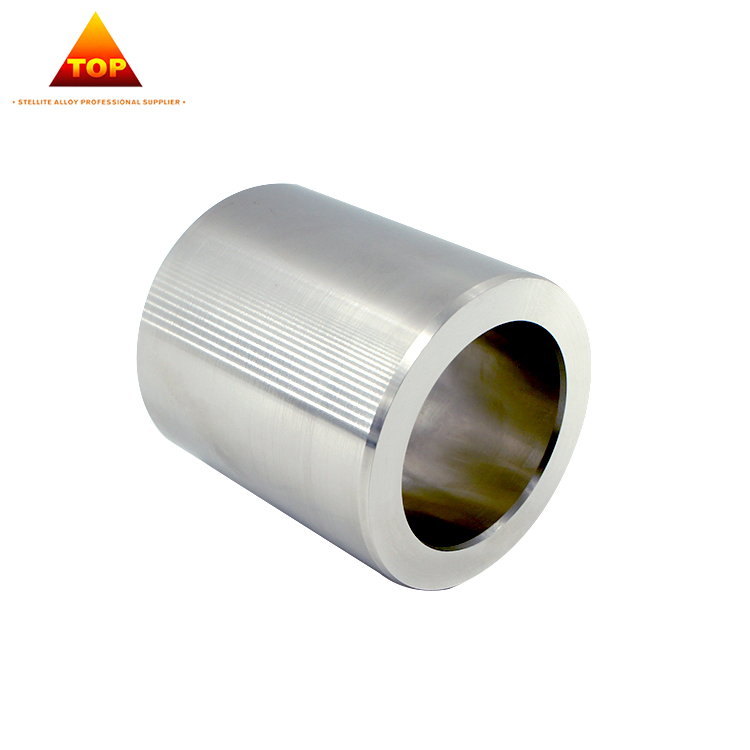

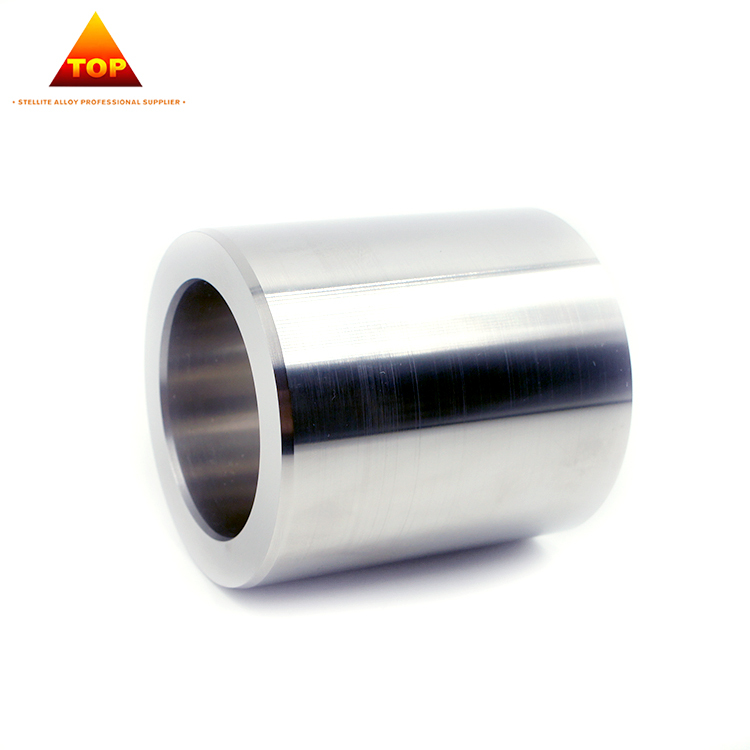

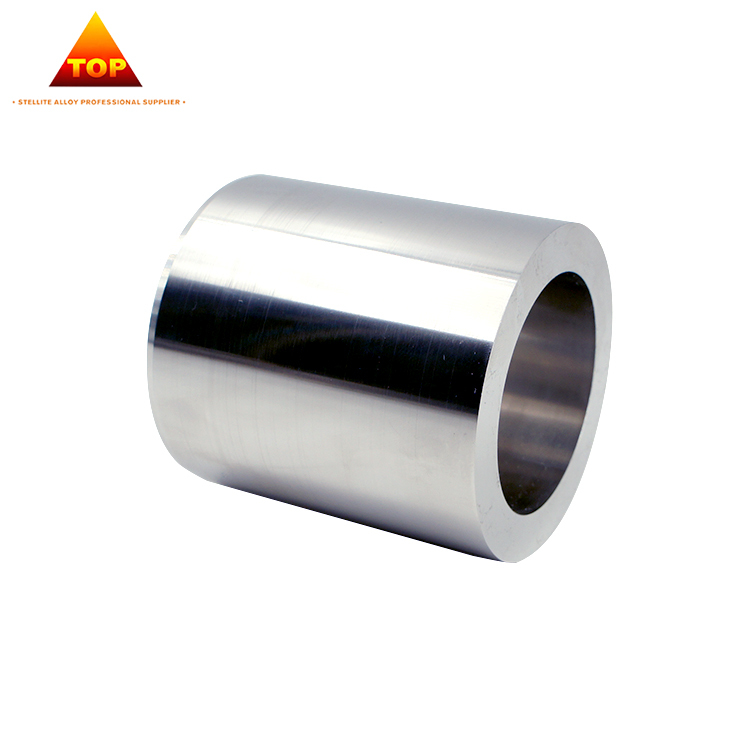

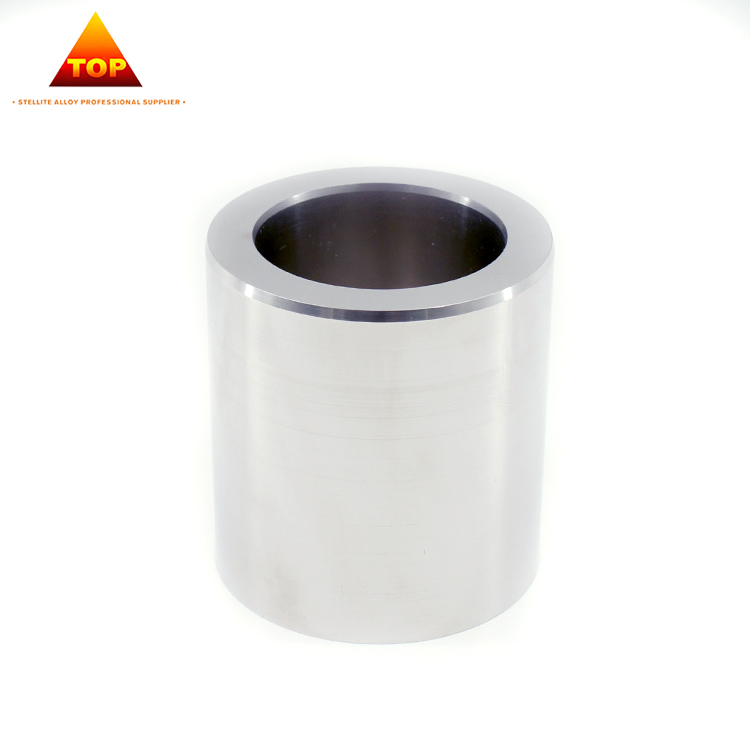

Cobalt Alloy Bearing Bush For Steam Turbine

Addressing water corrosion in steam turbine last-stage blades is critical to ensuring safe and efficient operation. Our Cobalt Alloy Bearing Bush provides a reliable solution, effectively mitigating corrosion risks. These bushings are meticulously brazed onto the blades, forming a protective barrier against water corrosion.

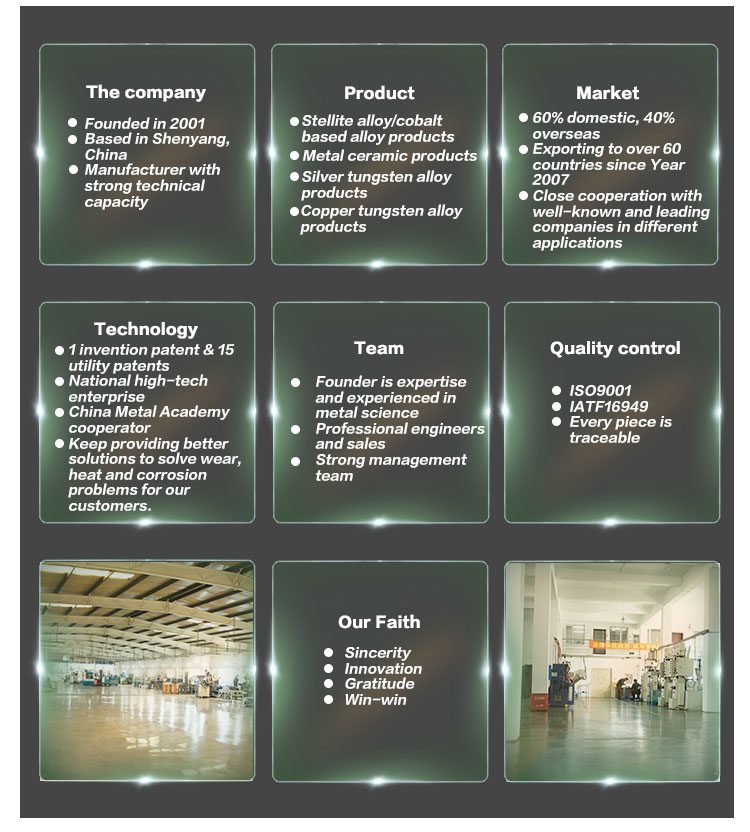

- SYTOP

- China

- 20-35days

- 3000pcs/ month

- Information

Cobalt Alloy Bearing Bush For Steam Turbine Blades

Due to the special working environment of the steam turbine's pipeline valve bushing, the bushing is required to have good high temperature resistance and steam corrosion resistance. Cobalt alloy solves the above problems very well. The temperature of the steam transported by the steam turbine is very high. And it is corrosive to valves and pipes, Cobalt alloy bushings can reduce downtime and replacement cycles.

1. Cobalt alloys have higher melting points than nickel (or iron) alloys ,This gives them the ability to absorb stress to a higher absolute temperature .

2. Cobalt alloys give superior hot corrosion resistance to gas turbine atmospheres , this is due to their high chromium content.

3. Cobalt alloys show superior thermal fatigue resistance and weldability over nickel alloys .

---Excellent wear and corrosion resistance even at high temperature up to 800℃

Chemical compositions and properties (%)

Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density (g/cm3) | Hardness (HRC) |

Cobalt Alloy 3(ST3) | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 | |

Cobalt Alloy 6(ST6) | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

Cobalt Alloy 12(ST12) | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 | |

Cobalt Alloy 20(ST20) | 2.2-3.0 | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.05 | ≤0.05 | 8.65 | 53-59 | |

Cobalt Allot T400 | 0.04 | 2.5-2.7 | 8-10 | 27-29 | Bal. | 55 | |||||||

Cobalt Alloy T 800 | 0.04 | 3.2-3.6 | 16-18 | 27-29 | Bal. | 58 |

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Specifications that we can made :

Different size bars , rods , ingots , plate

Drawing made seal , valve seat and ball , bush and sleeve etc.

Some size tube

Most of our products are made upon request so contact us right now for personal and professoinal service.

More details about cobalt chrome round bar please do not hesitate to contact me .