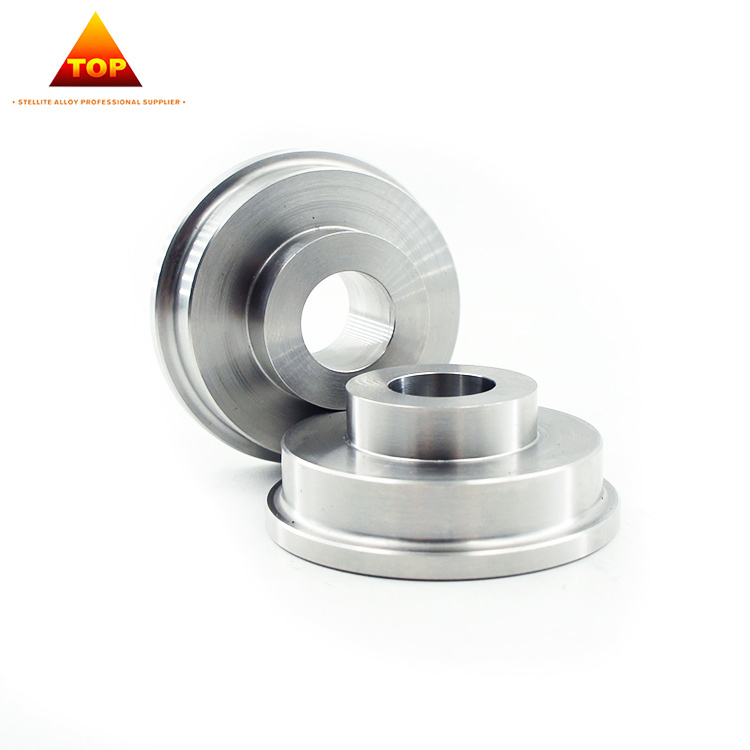

CObalt Alloy 20 Valve Seat for Homogenizer

We supply Co 20 valve wear and spare parts for homogenizers and high-pressure pumps. ST 20 has high hardness, is very hard to machine, but we have professional machinery can make sure that products will match your requirement.

If you need samples to test the capability, 1pc is acceptable.

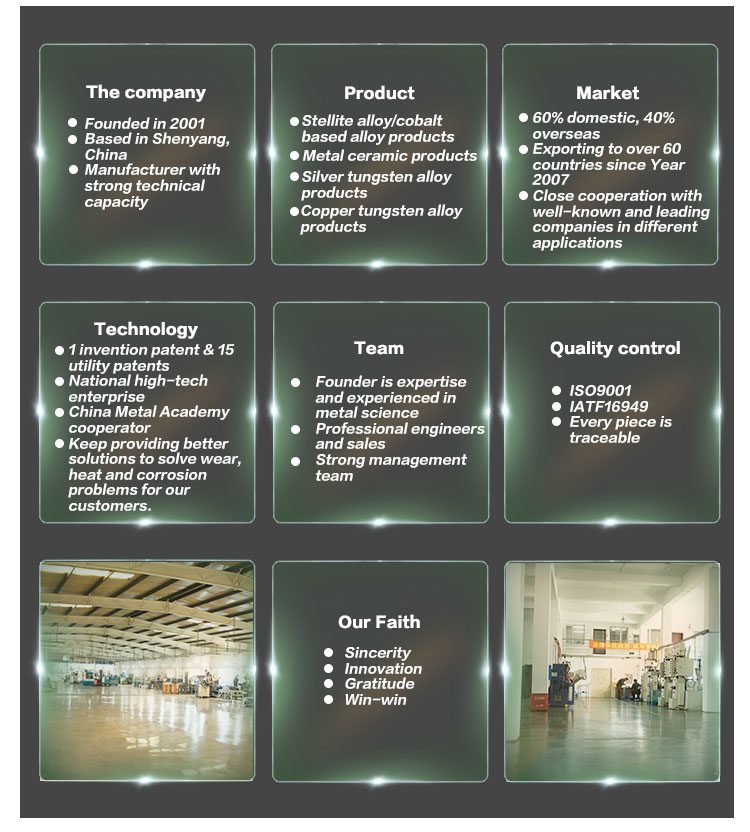

- TNM

- China

- 45days

- 100pcs/month

- Information

Cobalt Alloy 20 Valve Seat for Homogenizer Accessories

Food processing is to transform some edible things into something more delicious or more beneficial to us through certain operations. The process of artificially processing raw grains or other raw materials into a new product that can be eaten directly is food processing.

Cobalt alloys are mainly used in homogenizers. As a material that has wear resistance and corrosion resistance without affecting health, it is widely used in some food processing machinery.

Chemical compositions and properties (%)

Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density (g/cm3) | Hardness (HRC) |

ST 20 | 2.3-3.0 | 1.0 | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.65 | 56-60 |

ST 6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.30 | 38-44 |

ST 12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 |

Features:

Optimal Sealing: The valve seat provides an impeccable seal, preventing unwanted leakages and ensuring efficient operation.

Robust Design: Crafted from ST 20, the valve seat is resistant to wear and corrosion, making it ideal for prolonged use.

Versatility: Compatible with a range of homogenizer systems, offering flexibility in its application.

Enhanced Flow Control: The design ensures that the fluid flows smoothly, reducing turbulence and enhancing efficiency.

Applications:

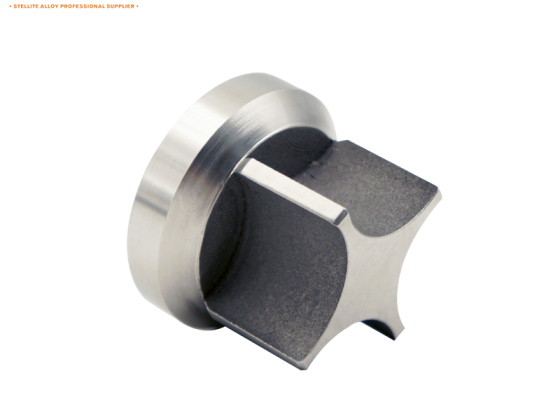

Flow Control: Plays a pivotal role in controlling the flow of fluids in homogenizer systems.

High-Pressure Environments: Its robust design makes it suitable for systems that operate under intense pressures.

Industrial Processing: Commonly used in industries that require precise flow control, such as the food and beverage sector.

SYTOP cobalt 20 alloy is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Specifications that we can made :

Different size bars, rods, plate

Drawing made seal , valve seat and ball , bush and sleeve etc.

Most of our products are made upon request so contact us right now for personal and professoinal service.

More details about cobalt chrome round bar please do not hesitate to contact me .