Cobalt Alloy Wear Strips For Steam Turbine

The last stage blades of the steam turbine are prone to water corrosion, and the failure of the blades leads to the unsafe operation of the steam turbine. The cobalt alloy blade anti-corrosion sheet properly solves the problem, and the cobalt alloy anti-corrosion sheet is welded to the blades by brazing. , effectively prevent the water corrosion of the steam turbine blades, and improve the safety and economy of the normal operation of the steam turbine.

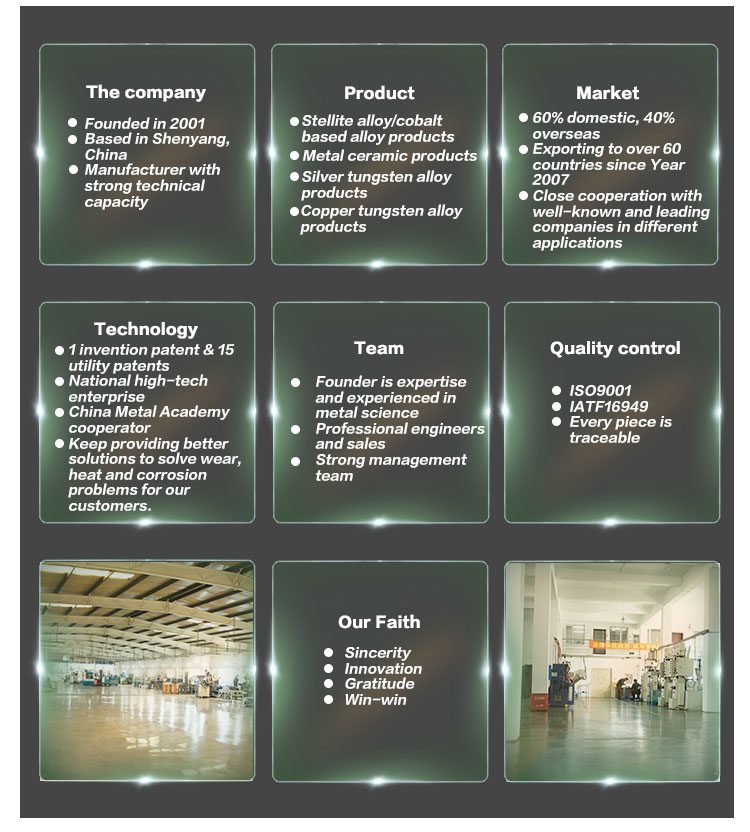

- SYTOP

- China

- 25-45days

- 3000pcs/ month

- Information

Cobalt Alloy Steam Turbine Wear Strips

Cobalt alloy is a cobalt-based cemented carbide that is resistant to various types of wear and corrosion, as well as high temperature oxidation. Invented in 1907 by American Elwood Hayness. Cobalt alloys are mainly composed of cobalt, containing a considerable amount of nickel, chromium, tungsten and a small amount of alloying elements such as molybdenum, niobium, tantalum, titanium, and occasionally iron. Our company adopts powder metallurgy, casting, forging, welding and other processes to ensure the excellent performance of materials. Among them, the powder metallurgy technology is particularly mature, the product performance is stable, the precision is high, and mass production can be carried out. Cobalt alloys are suitable for conditions that require both high temperature resistance, wear resistance and corrosion resistance. The more complex working conditions are, the more the advantages of cobalt alloys can be reflected.

---Excellent wear and corrosion resistance even at high temperature up to 800℃

Chemical compositions and properties (%)

Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density (g/cm3) | Hardness (HRC) |

Co 3 | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 | |

Co 6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

Co 12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 | |

Co 20 | 2.2-3.0 | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.05 | ≤0.05 | 8.65 | 53-59 | |

Tantung-G 25 | 2.2-2.8 | 1-3 | 27-32 | 7 | Ta/Nb | 14-19 | Bal. | 2-5 | 8.84 | 57-60 | |||

Tantung-G35 | 3.3-3.8 | 1-3 | 27-32 | 7 | Ta/Nb | 14-19 | Bal. | 2-5 | 8.80 | 60-63 | |||

Tribaloy 400 | 0.04 | 2.5-2.7 | 8-10 | 27-29 | Bal. | 55 | |||||||

Tribaloy 800 | 0.04 | 3.2-3.6 | 16-18 | 27-29 | Bal. | 58 |

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Specifications that we can made :

Different size bars , rods , ingots , plate

Drawing made seal , valve seat and ball , bush and sleeve etc.

Some size tube

Most of our products are made upon request so contact us right now for personal and professoinal service.

More details about cobalt chrome round bar please do not hesitate to contact me .